- Home

- About us

- Products

- Disposable Wooden Cutlery Wholesale

- Ice Cream Sticks and Spoons Wholesale

- Coffee Stirrers Wholesale

- Skewers Wholesale

- Disposable Chopsticks Wholesale

- Toothpicks Wholesale

- Disposable Wooden Food Containers Wholesale

- Eco-friendly Straws Wholesale

- Disposable Wooden Medical Supplies Wholesale

- Disposable Wooden Beauty Salon Supplies Wholesale

- Faqs

- News

- Certificate

- Contact us

YADA's Premium Wooden Ice Lolly Sticks: Pioneering Safety and Quality in the Ice Cream Industry

publisherJessy

time2025/01/08

- Discover YADA's commitment to excellence with SGS-certified, food-grade wood ice lolly sticks. Our products undergo rigorous testing for safety, quality, and performance, exceeding industry standards.

Elevating Ice Cream Production with YADA's Superior Ice Lolly Sticks and Spoons

In the rapidly evolving world of frozen treats, where innovation meets tradition, one element stands out as a crucial component in the creation of these delightful desserts: the humble ice lolly stick and spoon. These seemingly simple tools play an indispensable role in the automated production lines that bring joy to millions of consumers worldwide. At YADA, we understand the significance of this role, and we have dedicated ourselves to crafting ice cream sticks and spoons that not only meet but exceed the highest industry standards.

The YADA Difference: A Commitment to Excellence

At YADA, our mission is clear: to provide the ice cream and popsicle manufacturing industries with wood and bamboo-based products that are both functional and safe. We specialize in producing ice lolly sticks and spoons that are meticulously designed to integrate seamlessly into the automation processes of ice cream and popsicle factories. Our products are tailored to support the efficiency and reliability of these operations, ensuring that every product that leaves the factory floor is of the utmost quality.

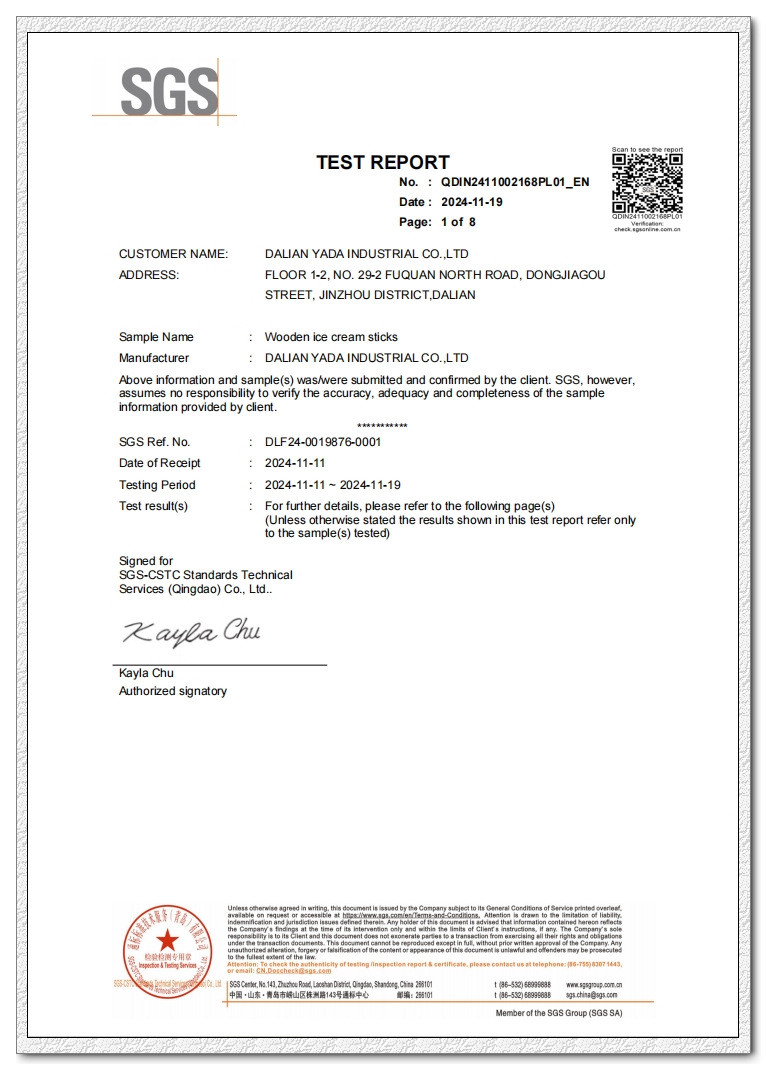

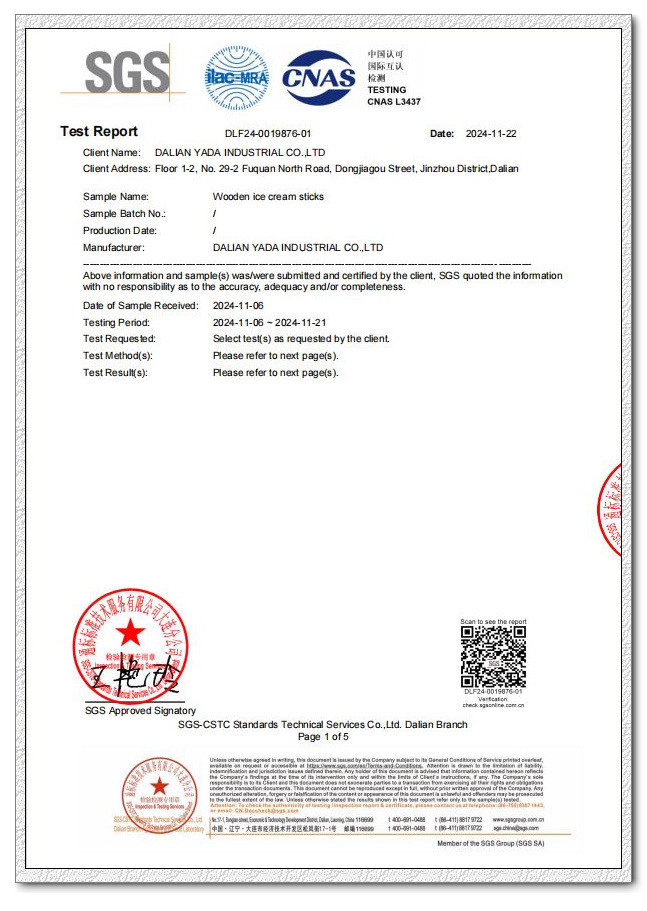

SGS Certification: A Milestone in Quality Assurance

The year 2024 marked a significant milestone for YADA, as we successfully obtained newly SGS certification, further solidifying our commitment to quality and safety. This certification is not just a badge of honor; it represents a rigorous evaluation of our production processes, from raw material selection to final product delivery. The SGS certification ensures that our ice lolly sticks and spoons meet stringent international standards, providing our clients with the peace of mind they deserve.

Comprehensive Testing: Beyond Industry Standards

To ensure that our products are of the highest caliber, YADA has implemented a comprehensive testing protocol that goes beyond the basic requirements set by national and international standards. Our testing process includes several key areas:

1. Sensory Evaluation: Ensuring a Perfect User Experience

Each batch of ice cream sticks undergoes a detailed sensory evaluation to ensure that they meet the highest standards of cleanliness, smoothness, and odor. We check for any signs of contamination, ensuring that the surface is free from pollutants. The texture is carefully examined to guarantee a smooth, splinter-free finish, while the natural aroma of the wood or bamboo is preserved, free from any foreign odors. Additionally, we inspect the packaging to ensure it is intact and free from damage, maintaining the integrity of the product during transportation.

2. Material Inspection: Flawless from Start to Finish

The quality of the raw materials used in our ice cream sticks is paramount. We conduct thorough inspections to ensure that each piece of wood or bamboo is free from defects such as insect holes, knots, decay, and mineral streaks. Consistency in color is also a critical factor, as it affects the overall appearance and aesthetic appeal of the product. By adhering to strict material standards, we ensure that our ice lolly sticks are not only functional but also visually appealing.

3. Dimensional Accuracy: Precision in Every Detail

Precision is key when it comes to the dimensions of our ice lolly sticks. Each product is measured to ensure that it meets the exact specifications required for optimal performance in automated production lines. We verify the length, width, and thickness of each stick to ensure consistency across all batches. This attention to detail guarantees that our products will fit perfectly into the machinery, reducing the risk of jams or other production issues.

4. Processing Quality: Minimizing Defects

During the manufacturing process, external factors can sometimes introduce defects into the product. To address this, we have developed a detailed inspection process that identifies and eliminates any processing defects. We examine the surface of each ice cream stick for signs of damage, such as scratches, dents, or uneven edges. By catching these issues early, we ensure that only the highest-quality products reach our customers.

5. Moisture Content: Balancing Durability and Flexibility

The moisture content of the wood or bamboo used in our ice lolly sticks is carefully monitored. Too much moisture can lead to warping, cracking, or even rotting, while too little can make the material brittle and prone to breaking. We conduct batch-by-batch testing to ensure that the moisture content is within the optimal range, providing a balance between durability and flexibility. This careful control ensures that our products maintain their integrity throughout the production process and beyond.

6. Microbiological Testing: Safeguarding Consumer Health

Safety is non-negotiable when it comes to food-contact products. YADA takes this responsibility seriously by conducting extensive microbiological testing on our ice cream sticks. We test for bacteria such as Staphylococcus aureus and other pathogens that could pose a risk to consumer health. By ensuring that our products are free from harmful microorganisms, we provide a safer experience for end-users and help prevent foodborne illnesses.

7. Chemical Migration: Protecting Against Harmful Substances

In addition to microbial safety, we also focus on chemical migration, which refers to the potential transfer of harmful substances from the ice lolly sticks to the ice cream or popsicles. We test for various chemicals, including formaldehyde, sulfur dioxide, and pentachlorophenol, to ensure that they do not exceed the limits set by national and international standards. This rigorous testing helps protect consumers from exposure to potentially harmful substances, maintaining the safety and purity of the final product.

Customization: Personalizing Your Brand

At YADA, we understand that every brand has its unique identity. That's why we offer customization options for our ice cream sticks and spoons. Whether you prefer single-sided or double-sided printing, we can imprint your logo or branding elements onto the sticks, ensuring that your products stand out in the market. Our advanced printing technology allows for high-quality, durable prints that remain clear and legible, even after extended use.

Environmental Responsibility: Sustainable Practices

In an era where sustainability is becoming increasingly important, YADA is committed to environmentally responsible practices. We source our raw materials from sustainably managed forests, ensuring that our production processes have minimal impact on the environment. Additionally, we continuously explore ways to reduce waste and improve energy efficiency in our manufacturing operations. By choosing YADA, you're not only investing in quality but also supporting a company that cares about the planet.

A Bright Future: Innovation and Growth

As the demand for ice cream and popsicles continues to grow, so does the need for innovative solutions in the production process. YADA is at the forefront of this evolution, constantly researching and developing new technologies to enhance the performance and safety of our products. We work closely with our clients to understand their needs and challenges, offering customized solutions that meet the specific requirements of their production lines. Our dedication to innovation and customer service sets us apart in the industry, making us a trusted partner for ice cream and popsicle manufacturers worldwide.

Trust YADA for Quality and Safety

At YADA, we believe that the smallest details can make the biggest difference. From the careful selection of raw materials to the meticulous testing of each product, we leave no stone unturned in our pursuit of excellence. Our SGS certification, comprehensive testing protocols, and commitment to customization and sustainability demonstrate our unwavering dedication to providing the highest-quality ice lolly sticks and spoons. As the industry continues to evolve, YADA remains a leader in innovation and safety, ensuring that our products meet the needs of both manufacturers and consumers alike.

Choose YADA for ice lolly sticks and spoons that you can trust. Together, let's create a future where every ice cream and popsicle is a masterpiece of quality and safety.

YADA 120mm Eco-friendly Wooden Ice Lolly Sticks Wholesale | Birch Wood Round Lollies Stick for Candy

120mm,For Candy Machine Use, Non Jamming, High-quality, Standard Size, Non-toxic, Stable Inventory,Fast Shipping,Factory Price.

YADA 140mm Wooden Ice Lolly Sticks Wholesale | Birch Wood Lolly Stick | Round Lollies for Chocolates

140mm For Ice Lolly Machine, Non Jamming, High-quality, Standard Size, Non-toxic, Stable Inventory,Fast Shipping,Factory Price.

114mm Round Edge Bundle Popsicle Sticks Wholesale | YADA Birch Wood Stick for Ice Cream Machine Tool

MOQ: 10,000pcs, Size: 114×10×2mm, Bundle Packing, Birch Wood Stick Best for Automatic Production Line for Ice Cream or Popsicle

For Ice Cream Machine Use,Non Jamming,High-quality,Stanard Size,Non-toxic,Odorless,Stable Inventory,Fast Shipping,Factory Price